Precision Welding Solutions Inc. is an aluminum and stainless steel welding, machining and custom fabricating business specializing in high quality TIG welding.

- Our services include -

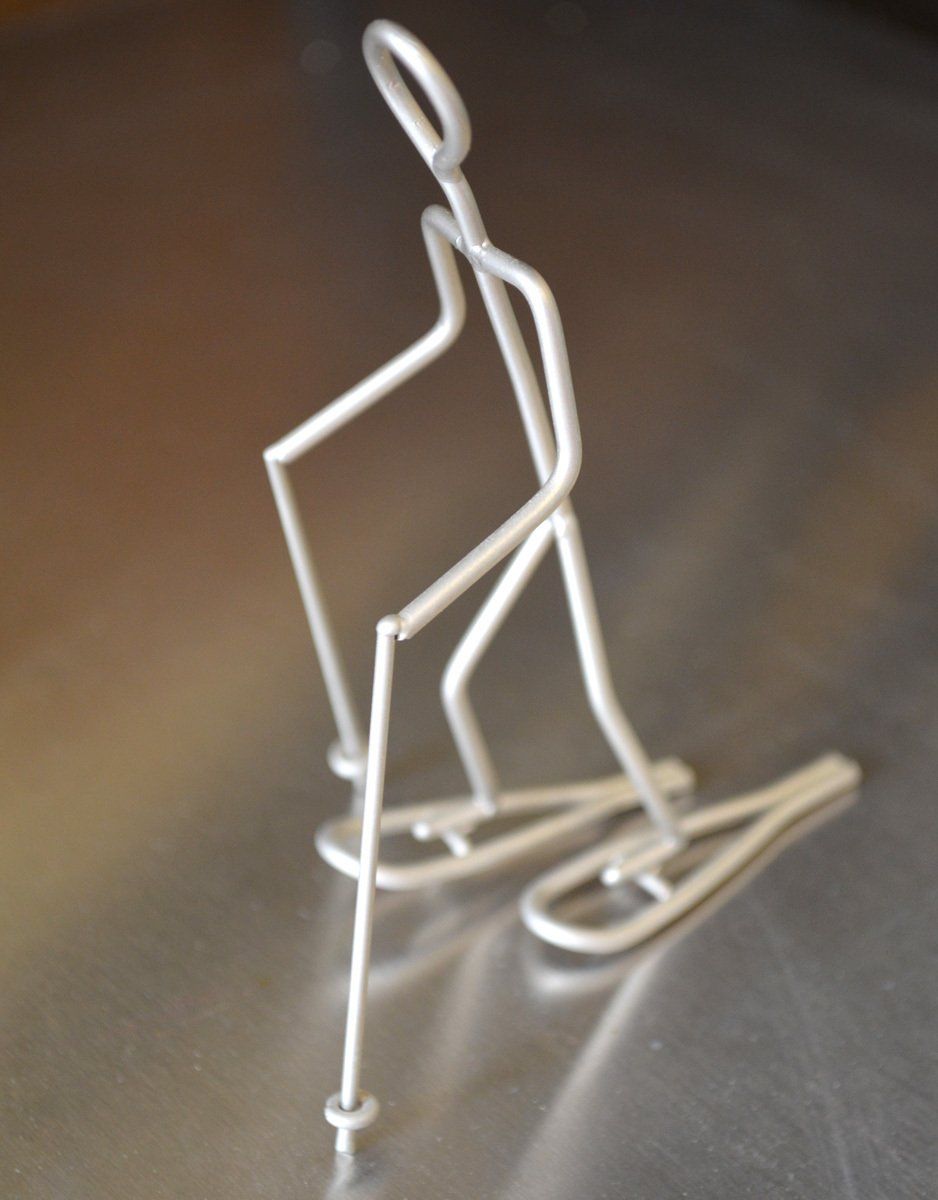

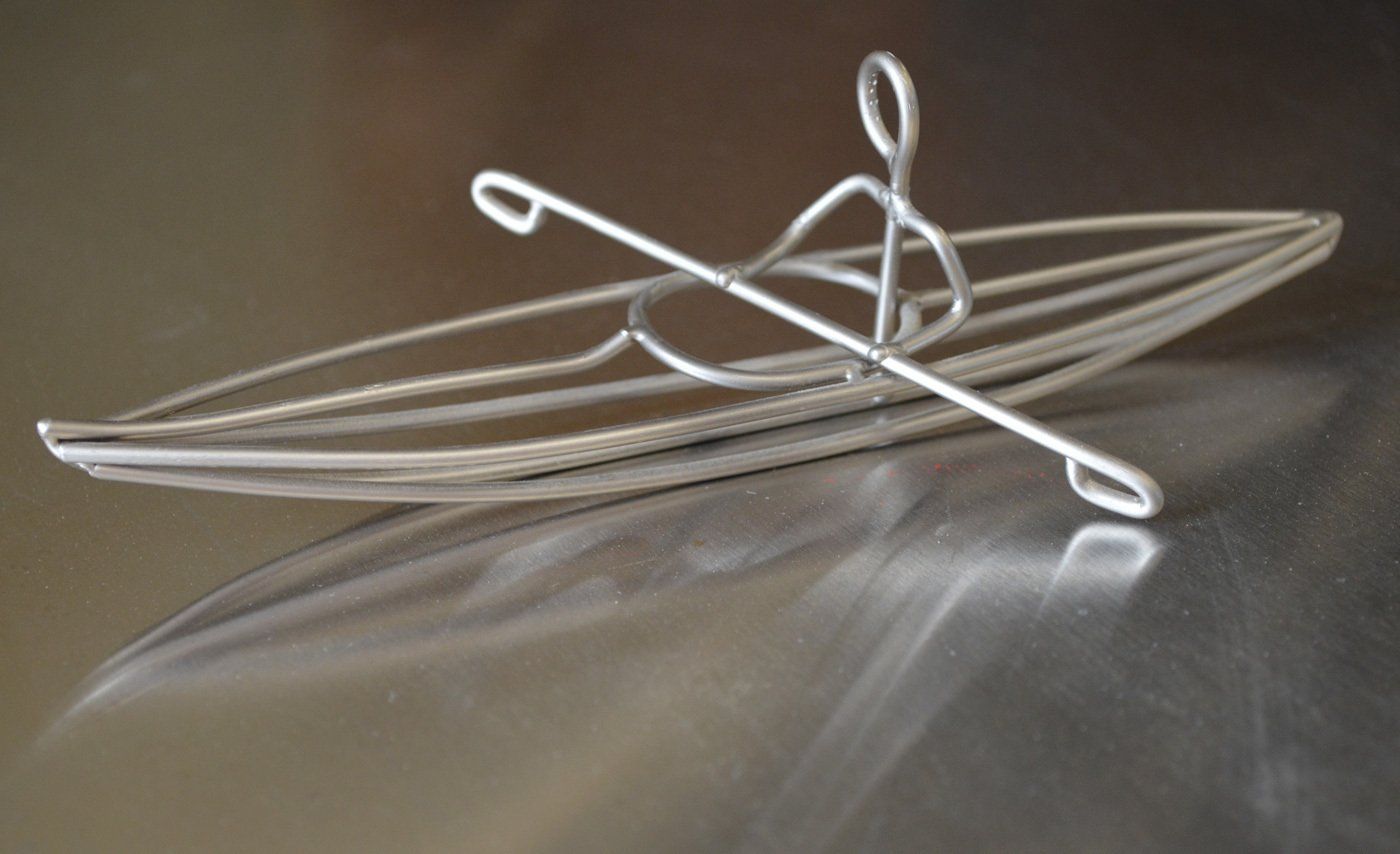

stainless steel welding, aluminum welding and repair, custom fabricating, machining, and custom metal furniture

We serve southern and central Ontario, across Canada and the United States.

ABOUTUS

Precision Welding Solutions

was established by Brian Honing who has over 20 years of experience in the aerospace, vacuum system and process piping industries. We draw from this experience to provide top quality services to customers in a variety of industries today.

"We have been providing welding, machining and custom fabrication services since 2003."

Whether you have complete drawings, a sketch on paper or need us to custom design a product, we would be happy to work with you on both small and large projects. We are proud of our reputation for delivering high quality products and excellent customer service at a competitive price.

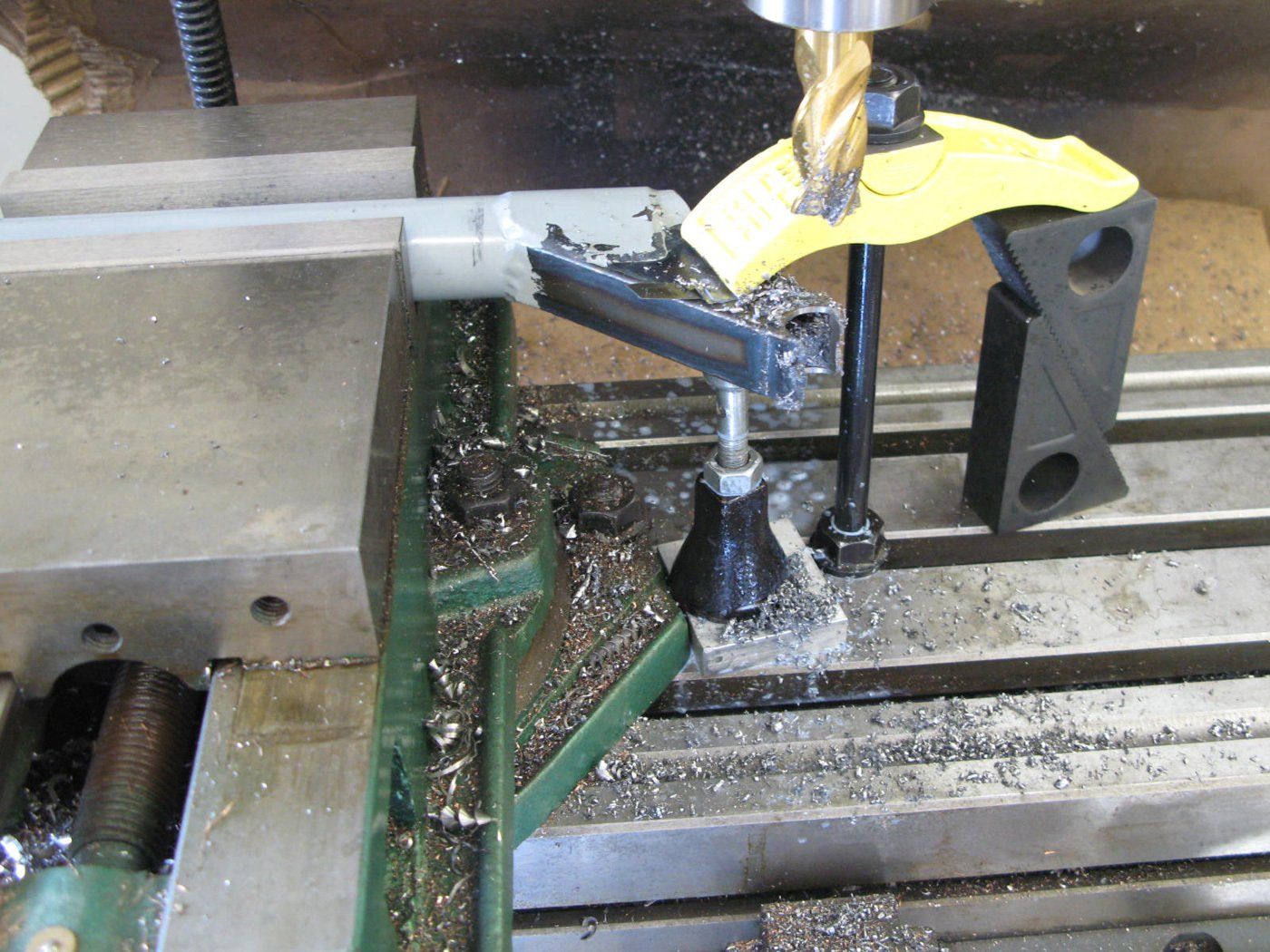

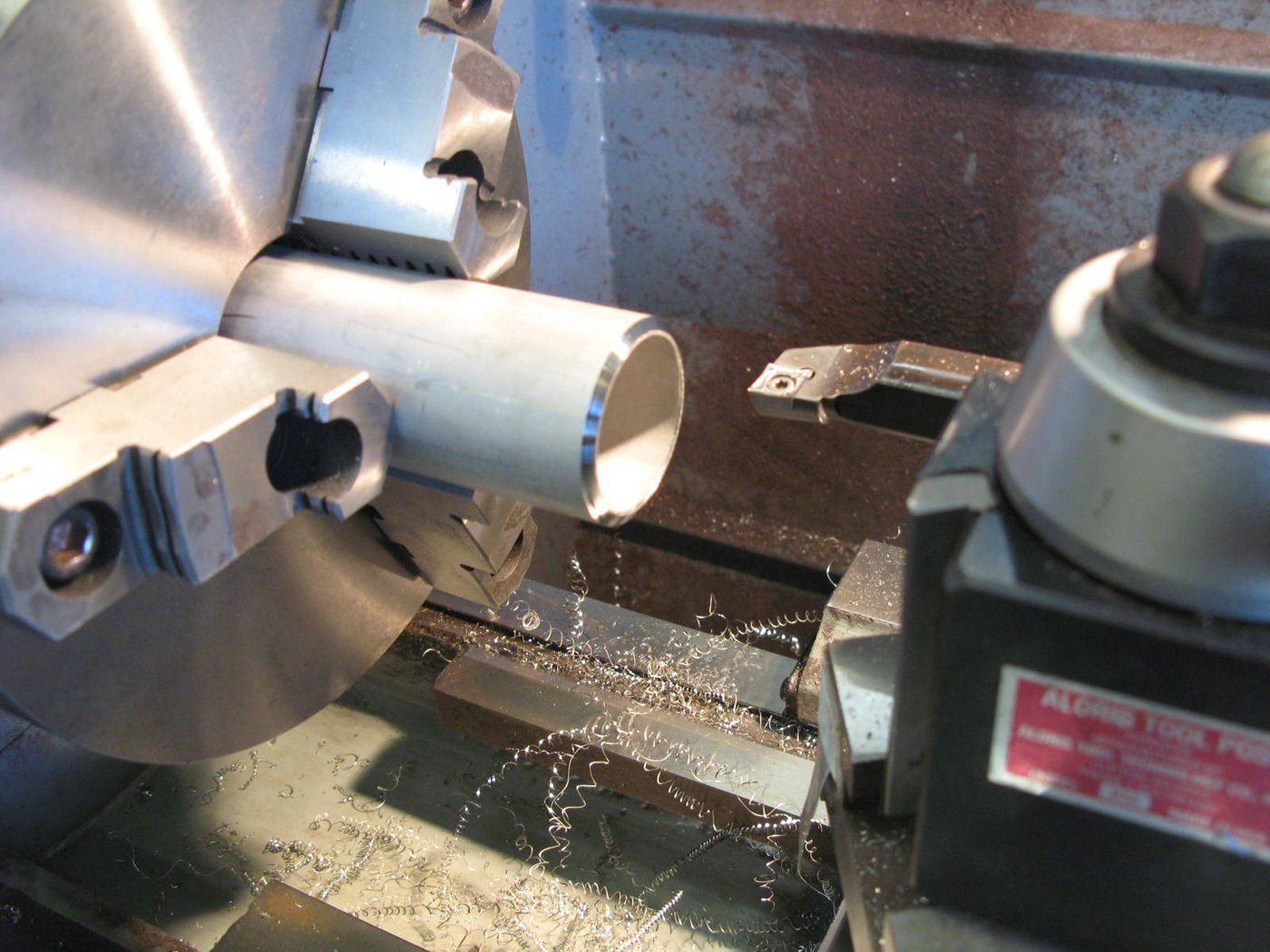

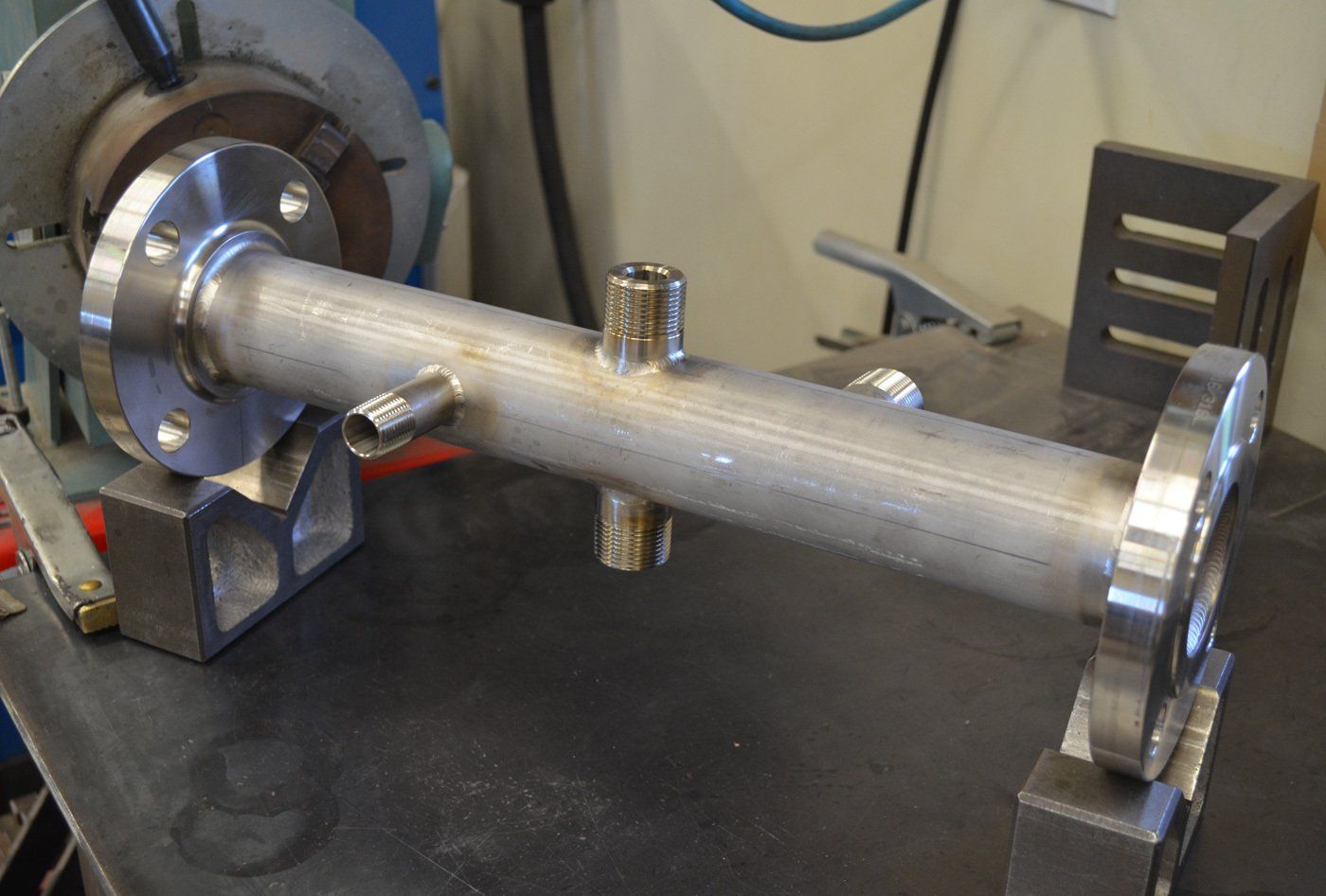

OURSERVICES

Precision Welding Solutions

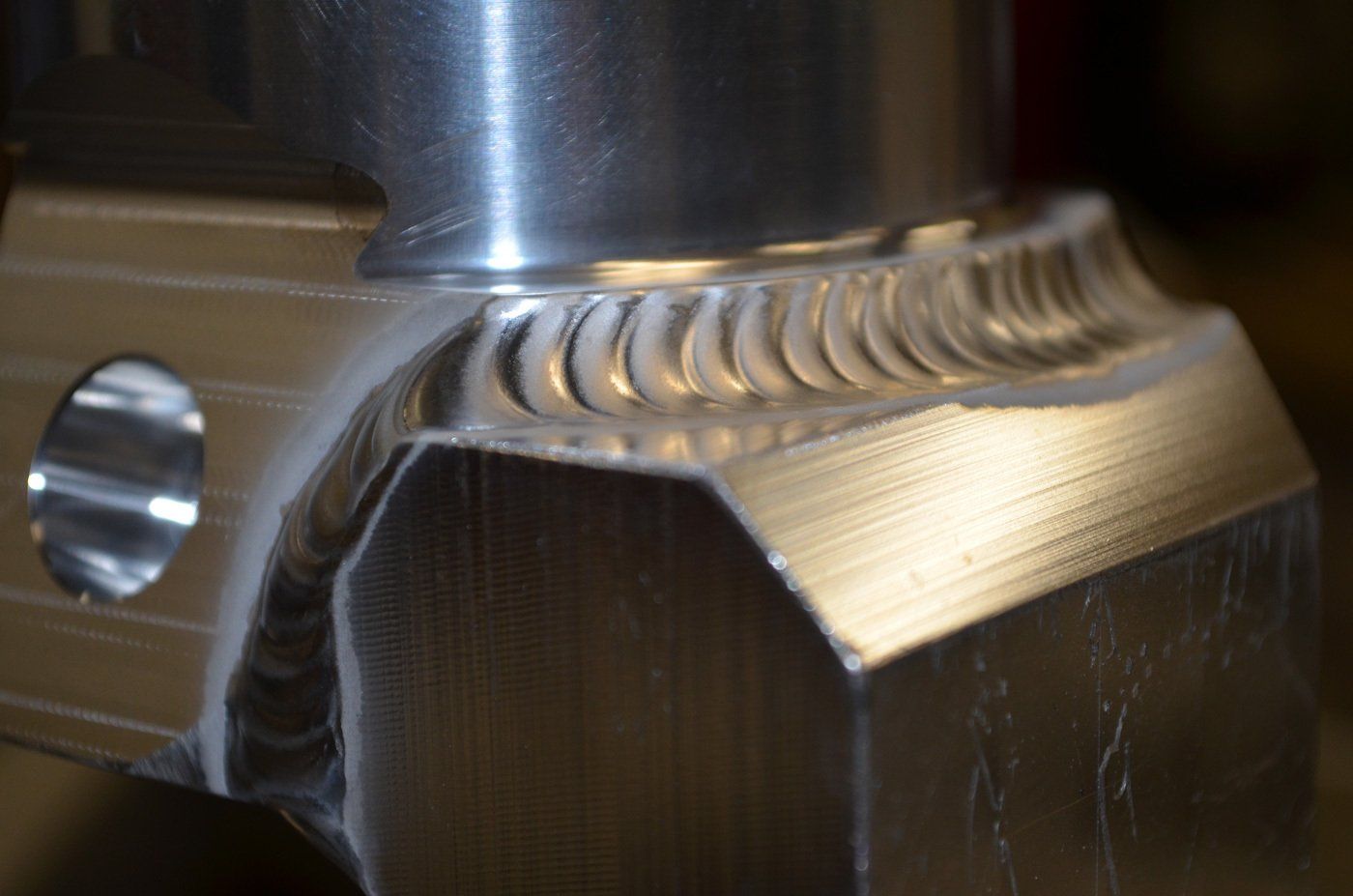

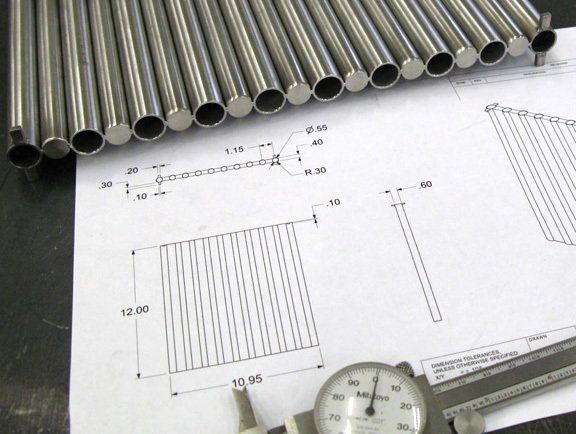

provides x-ray quality aluminum and stainless steel welding. The materials we work with are stainless steel, aluminum, copper, mild steel, tool steels, brass, magnesium and titanium.

These are some of the areas in which we are known for our quality workmanship:

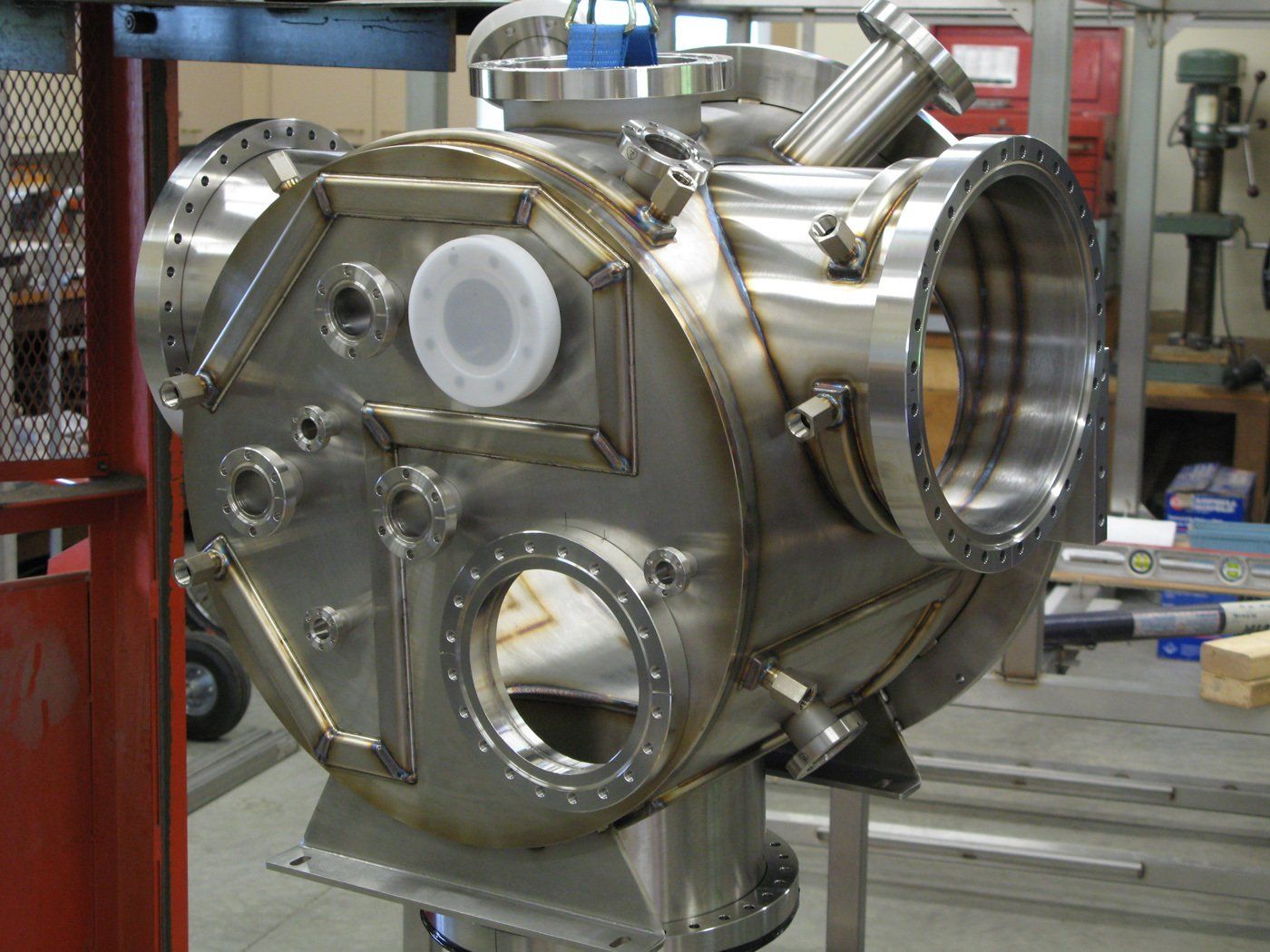

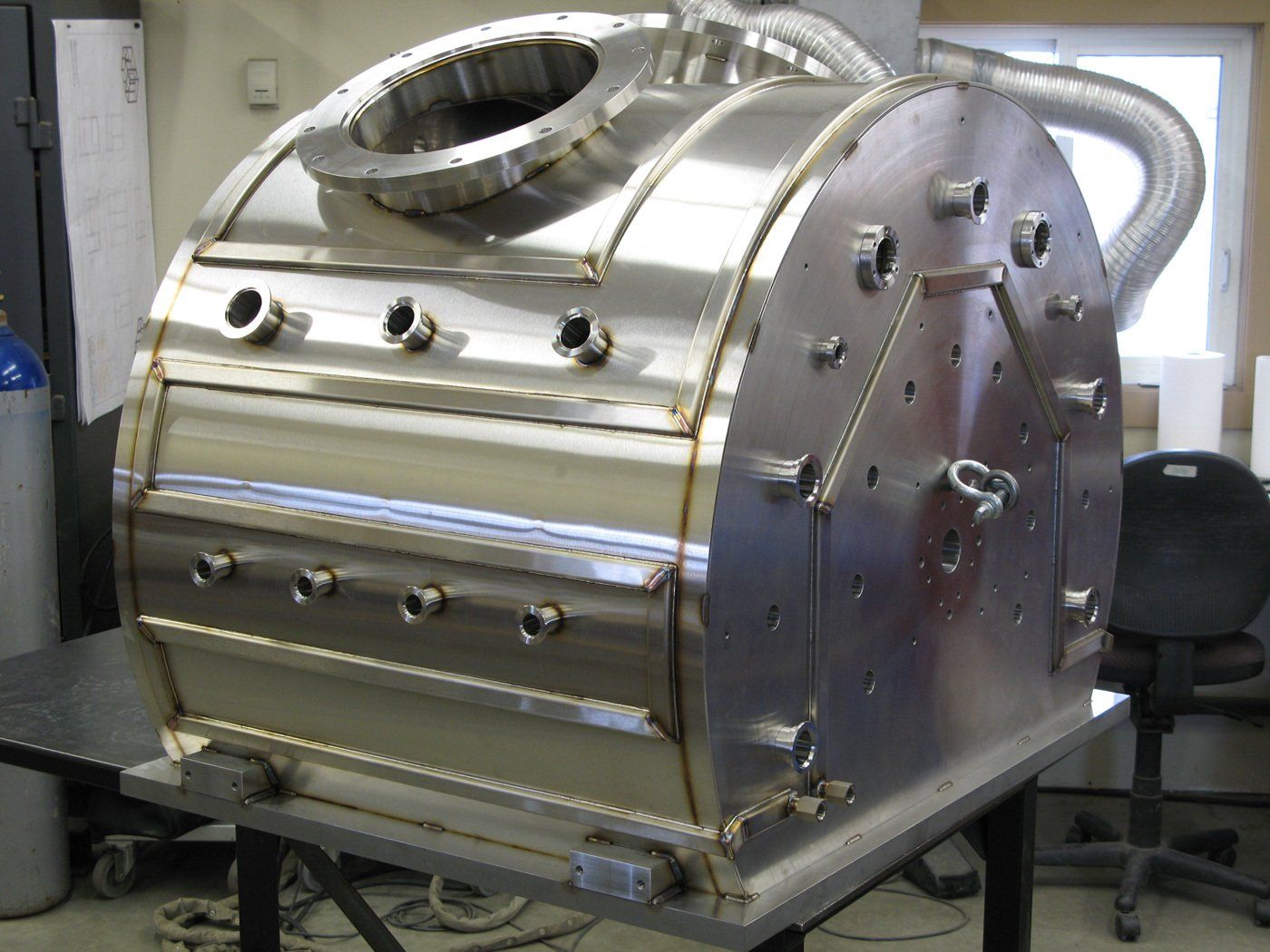

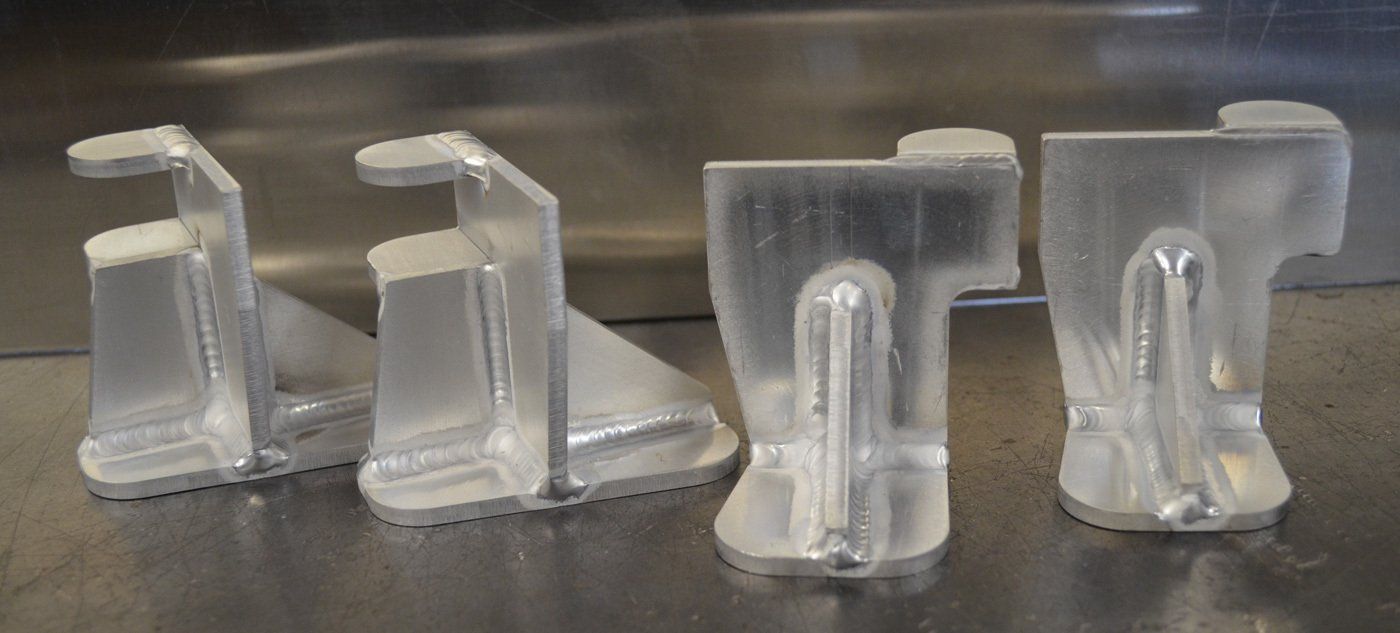

- welding and fabrication of ultra high vacuum chambers and components

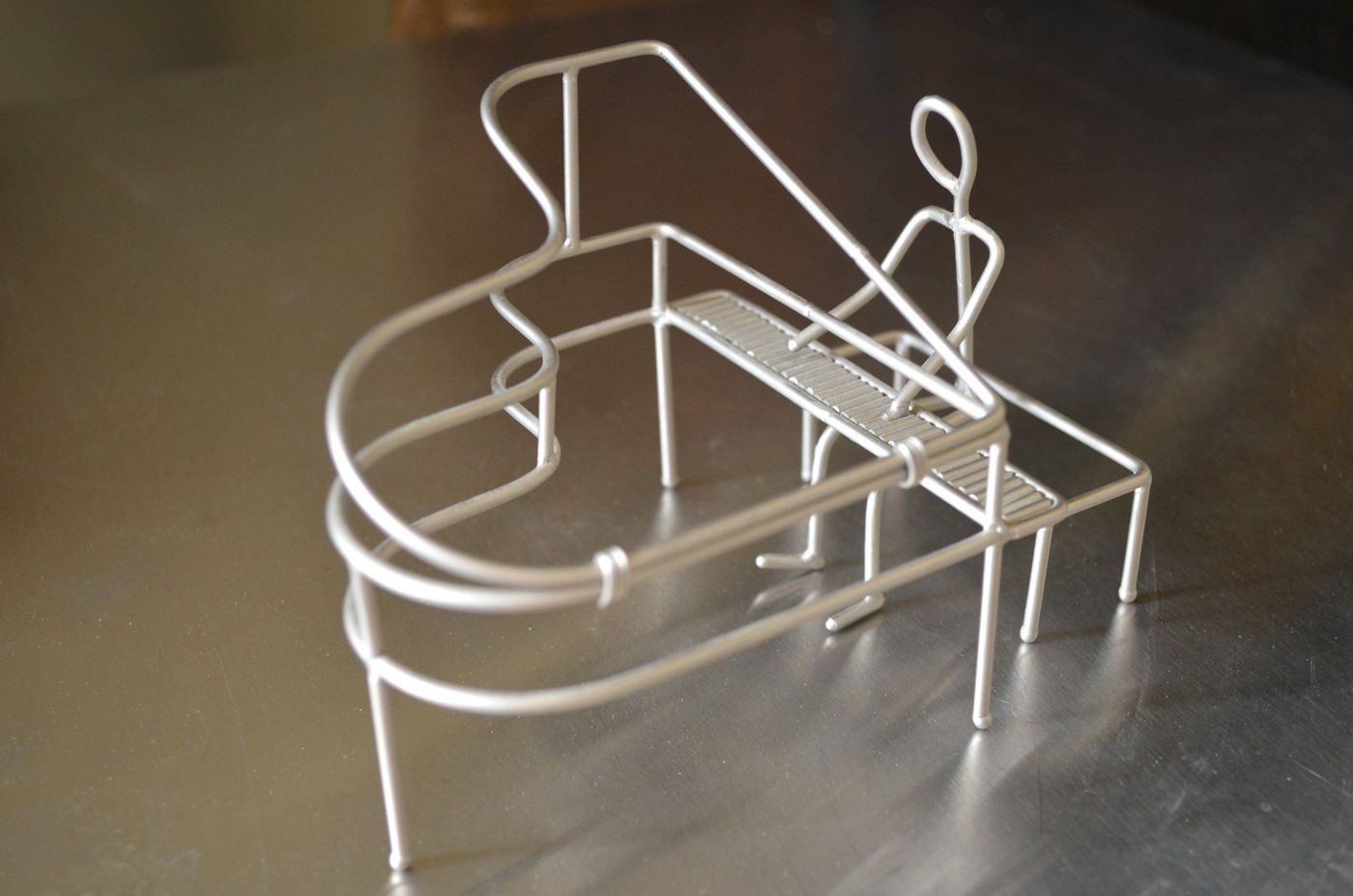

- manufacturing stainless and aluminum frames for various industries

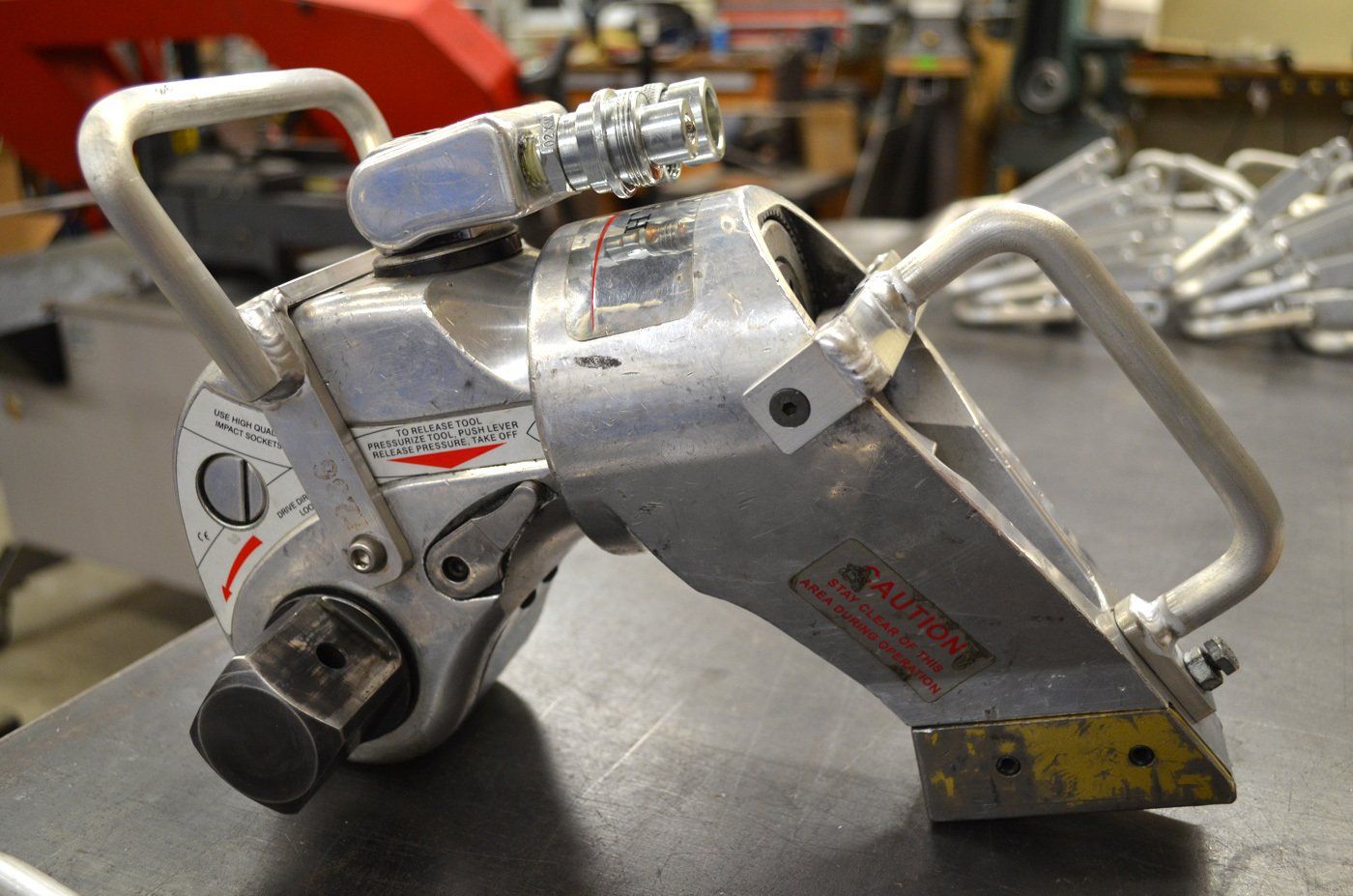

- specialized repairs on materials such as aluminum, copper, magnesium, and tool steels

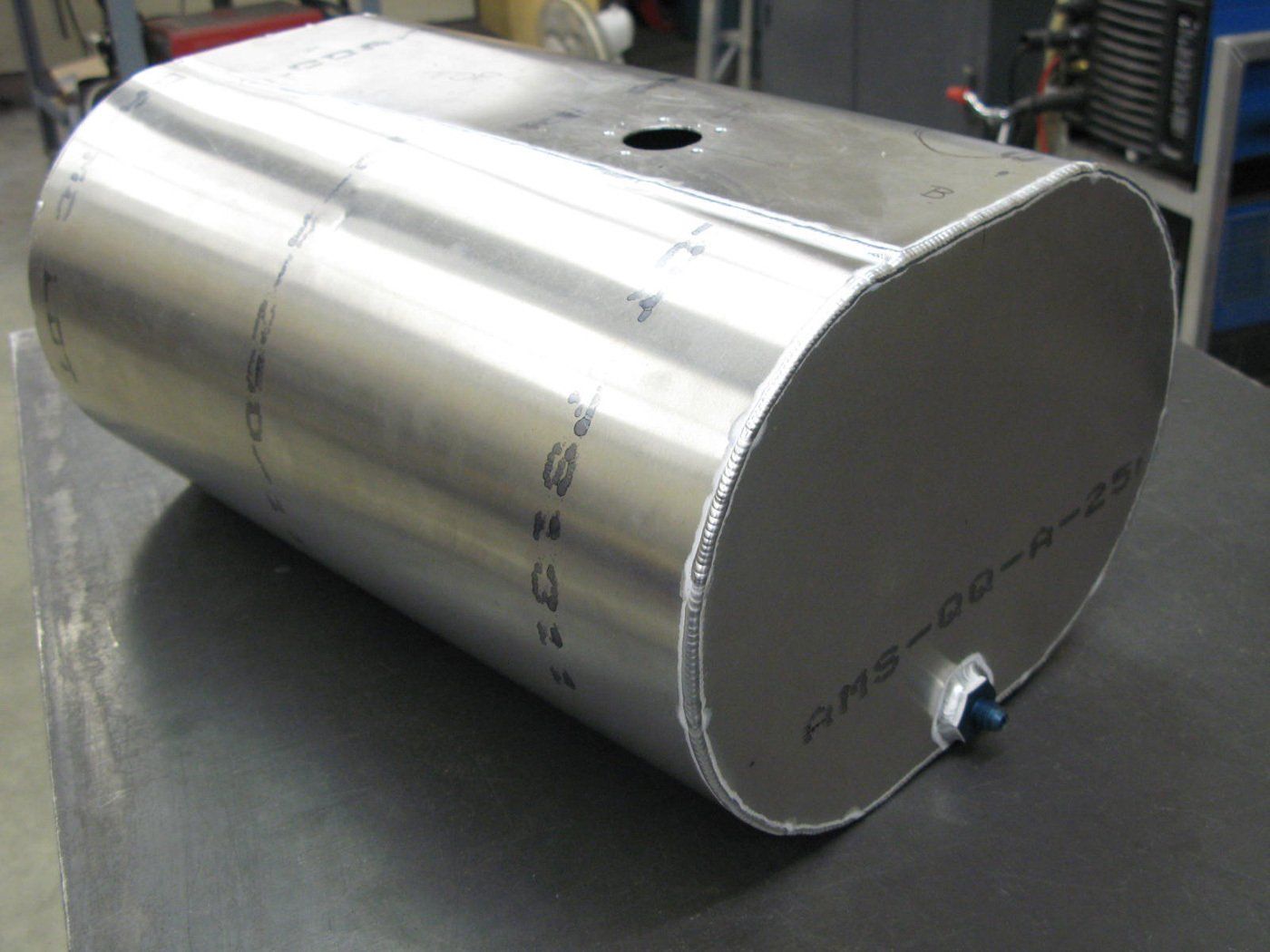

- custom fabrications including round and square tanks

- production welding

- custom steel furniture; steel legs for live edge tables / furniture - commercial and residential markets

- grinding and polishing of stainless steel

- refurbishing worn components and machining back to original spec

We are known for our ability to weld various thicknesses of aluminum, from 0.020 inches to several inches thick. Many of our aluminum jobs require x-ray and LPI testing; our stainless chambers require helium leak testing. We specialize in welding complex assemblies where tight tolerances must be maintained.

Working closely with a few suppliers we can facilitate: laser and water jet cutting, powder coating, high volume CNC machining, reverse engineering services, and full CMM inspection.

"We will deliver a high quality product with a quick turn around time."

Equipment

- Welding machines - Miller Dynasty 350; Dynasty 200 (1 - 200 amps); Miller Syncrowave 250

- 200 lb Atlas weld positioner with argon purge line

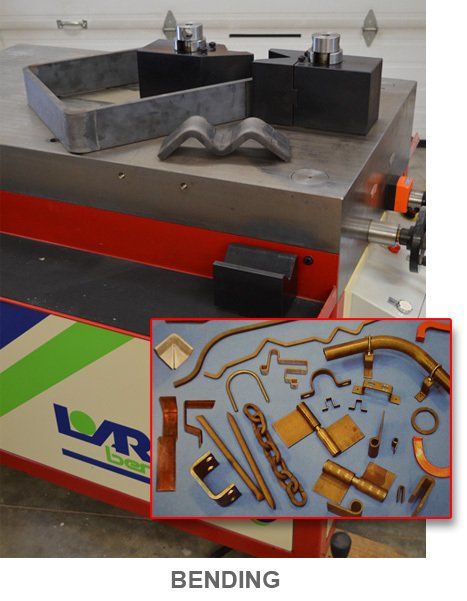

- 30 ton horizontal press brake

- Lathes with DRO

- Milling machine with DRO

- 10 ton Dake press

- Chain hoist

- Band saws

- Plasma cutter

- Inspection equipment including granite surface table

- Linear surface finishing equipment for stainless steel

- Table saw, planer, and various woodworking equipment

- Forklift

IMAGEGALLERY

CONTACTUS

Precision Welding Solutions Inc.

625173 Fifteenth Sideroad

Melancthon, Ontario

Canada L9V 1Z3

Phone: 519-925-0535

Cell: 519-216-9353

View from our shop window